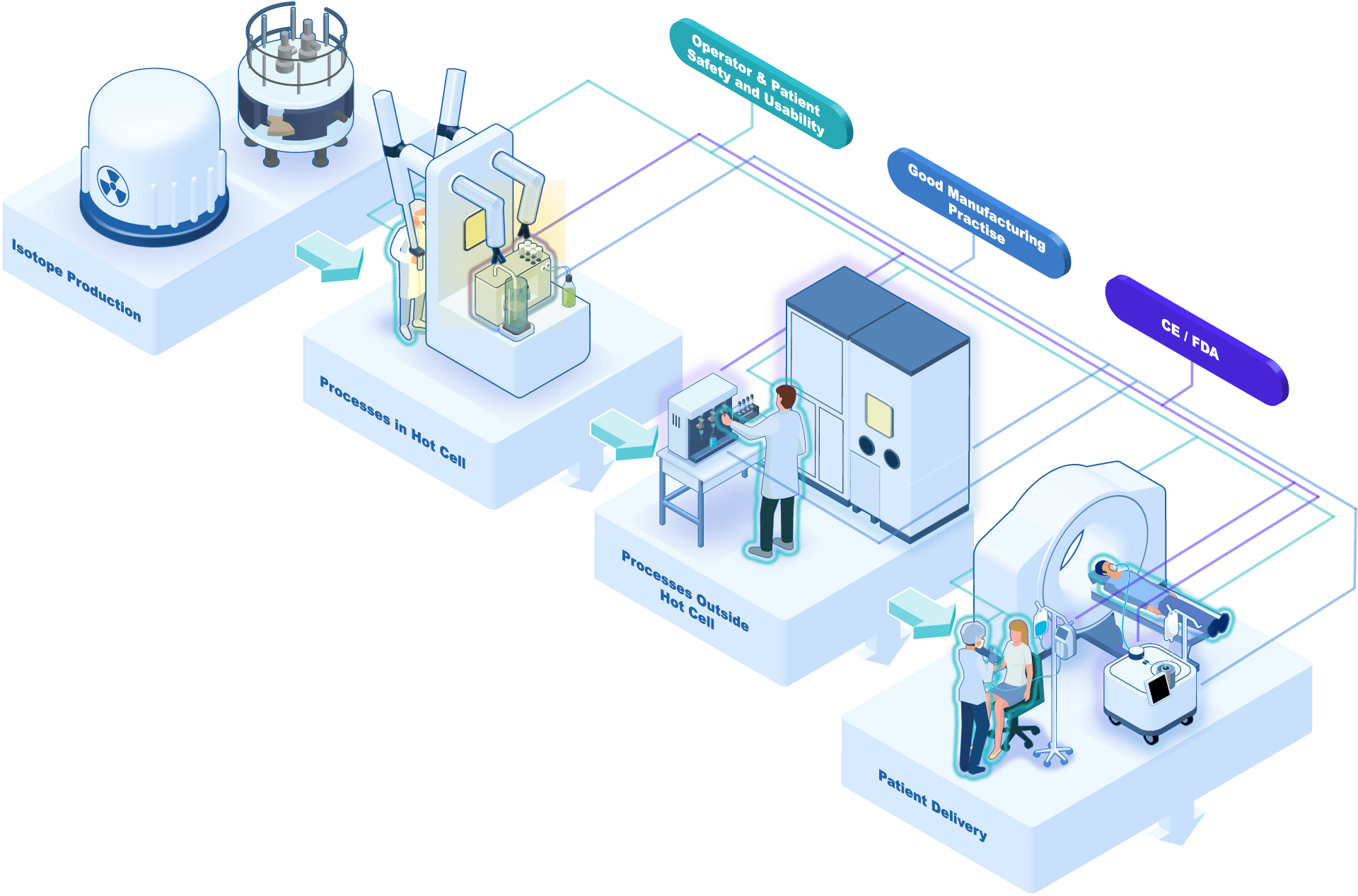

development support from production to patient care.

Nuclear medicine plays a vital role in modern healthcare by enabling precise diagnosis and targeted treatment through radioactive isotopes. As the field rapidly evolves, driven by breakthroughs in theranostics, radiopharmaceuticals, and molecular imaging, the demand for specialized engineering solutions is greater than ever.

- Regulatory-compliant development for radiopharmaceutical production and delivery.

- Tailored automation and robotics integration in production processes.

- User centered drug delivery systems for patient therapy.

what we offer.

-

We offer independent contract engineering for theranostic systems from production tooling to medical devices (GMP, CE, FDA).

-

Customers appreciate our expertise in smart hot cells, generators, and medical-grade, patient-specific innovations such as multi-dose injectors.

-

Our multidisciplinary team is skilled in systems and usability engineering for challenging radiation and patient environments.

"seamlessly integrating expertise to ensure the perfect technical fit for every project."

kit development with next generation 3D PEEK printing.

Together with Bond3D, we apply patented 3D printing technology to develop high-performance, near voidless components that maintain the full mechanical properties of PEEK, particularly its isotropic strength and chemical resistance. This enables the creation of lightweight, leak-tight manifolds and fluid handling kits with optimized flow and minimal part count, making them ideal for use in demanding medical and radiological applications.

The proven feasibility of this technology in critical environments translates seamlessly to systems handling radioactive or aggressive fluids, where precision, reliability, and safety are essential. By integrating functionality directly into printed components, we reduce part complexity and deliver compact, high-integrity solutions.

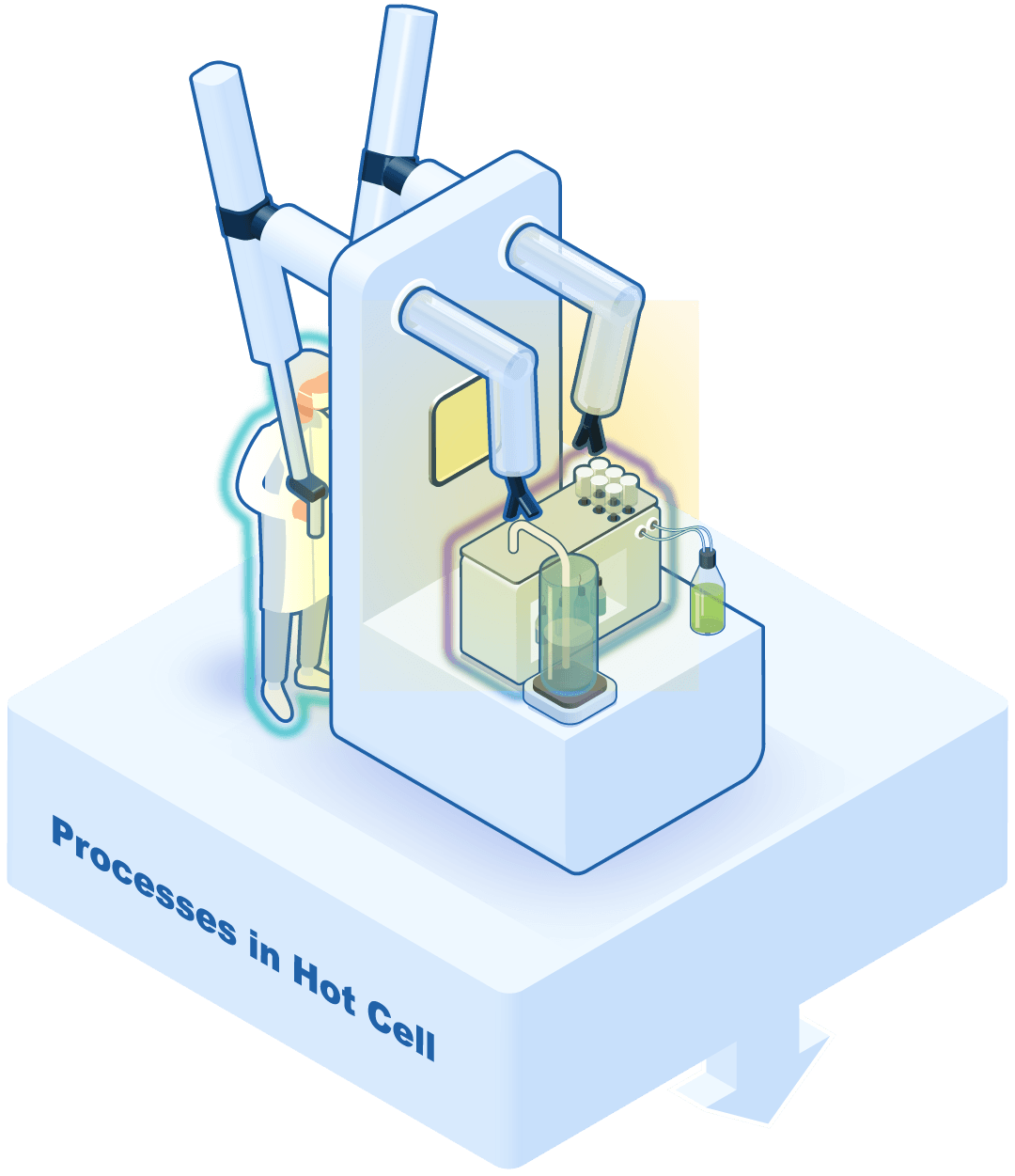

hot cell processes.

With co-creation we transform complex technical challenges into intuitive, high-performance systems. Often, it starts with a need for better usability—systems that not only function reliably but are also easy to operate and maintain. That’s where our expertise in usability engineering comes in. Whether it’s developing advanced telemanipulators for remote handling, automating processes with Beckhoff PLCs, or programming real-time control systems in C and Simulink, we bring together the right technologies to create seamless user experiences. Even in demanding environments, such as ATEX zones, we design robotics that are both safe and efficient.

In projects involving pneumatic and radiation-resistant systems, we engineer complex actuation and sensing solutions—often integrating custom electronics and lead-shielded cameras to meet strict radiation safety standards. In some cases, systems need to be partially placed inside and partially outside the hot cell to protect sensitive electronics from radiation-induced aging. Thanks to our ability to develop custom solutions, we can realize these hybrid configurations—tailored precisely to the functional and operational needs of each project.

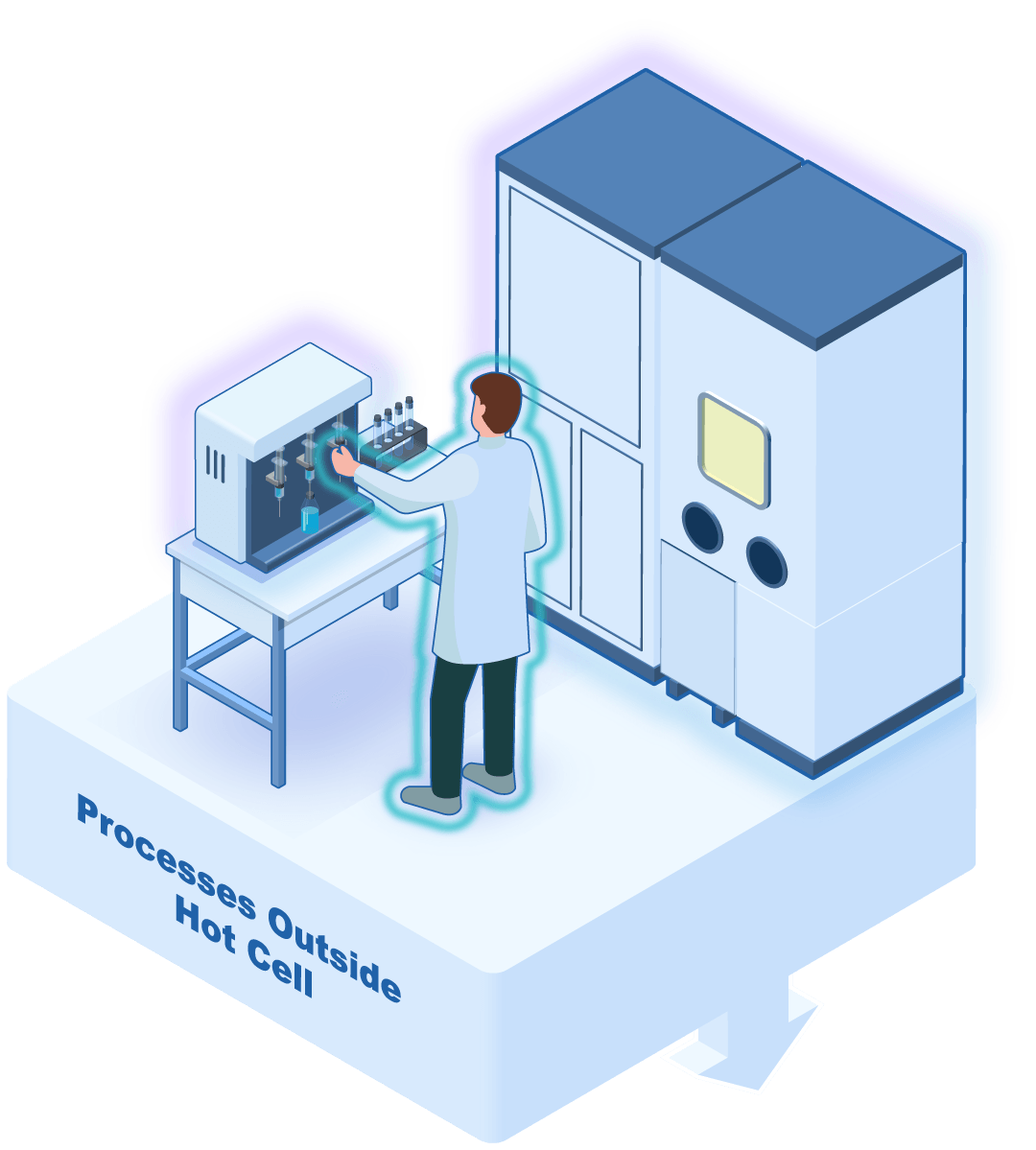

processes outside hot cell.

Handling fluids in high-precision environments demands more than just reliable flow—it requires smart, modular design. We develop leak-free systems built around disposable cartridges and kit-based assemblies, using high-performance materials like 3D-printed PEEK for chemical resistance and mechanical accuracy.

For automated dosing, precision is critical. Our systems control flow, temperature, and radiation dose with high accuracy, enabling bubble-free syringe filling and intelligent dose delivery. Every element is engineered to meet the highest standards of safety, compliance, and usability.

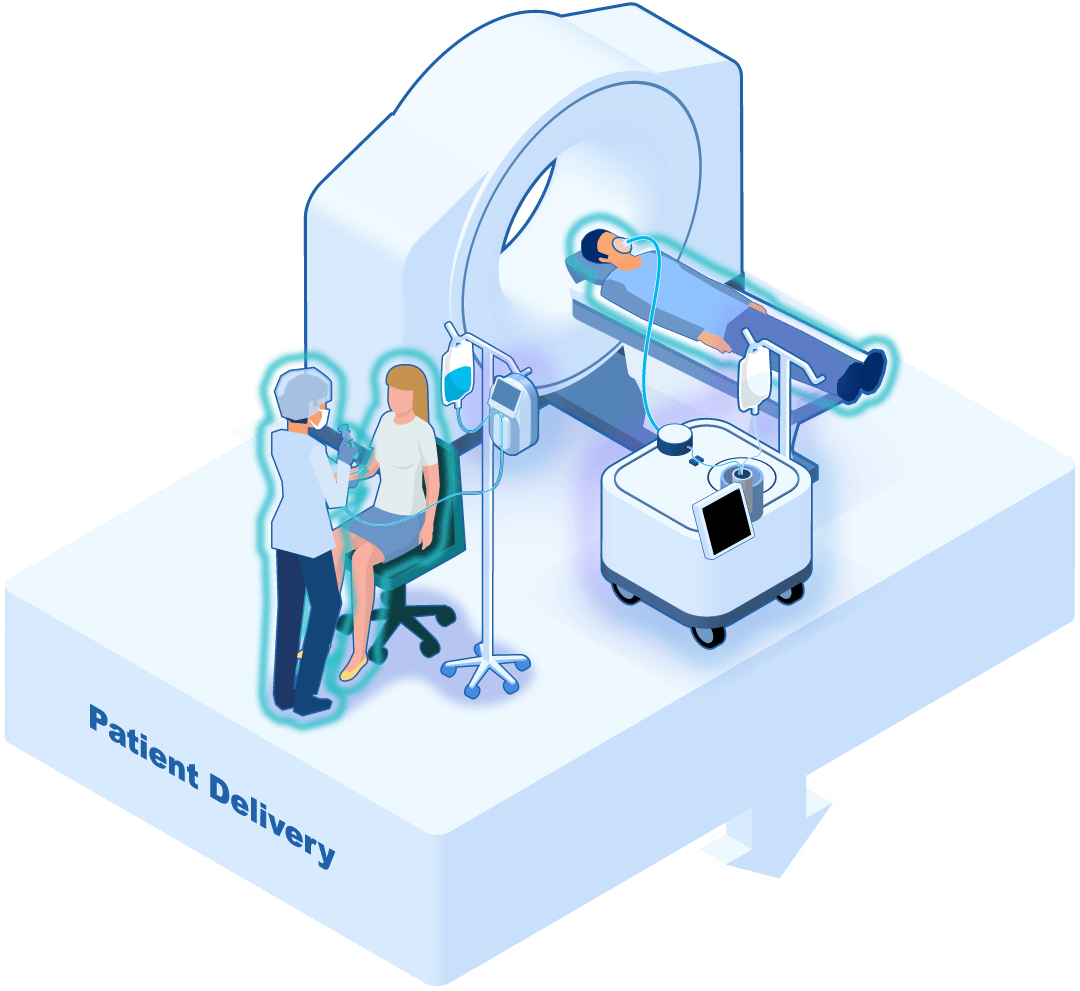

on-site generator and drug delivery.

As a development partner, we support companies in bringing isotope generation and drug delivery closer to the point of care by engineering GMP-compliant systems. Our solutions are tailored to accelerate product development while ensuring reliability, safety, and seamless integration into clinical environments.

We provide end-to-end support—from concept design and system architecture to prototyping, verification, and integration. With expertise in fluid handling, radiation shielding, thermal management, and process automation, we help our clients overcome technical challenges and meet regulatory requirements efficiently. Whether you're developing a compact generator, a precision drug delivery system, or shielded transport equipment, we bring the engineering capabilities to turn your vision into a validated solution.

sustainability engineering in every step.

Sustainability is always part of our approach. We critically assess material choices and system architecture to ensure long-term maintainability and minimal environmental impact.

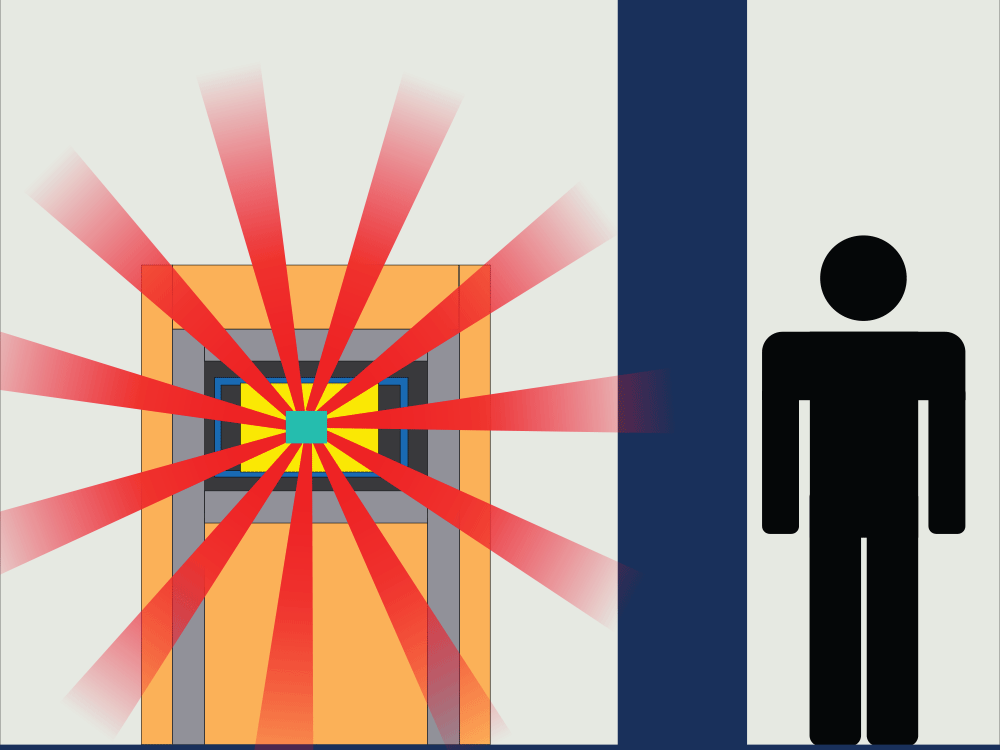

simulations using FLUKA.

With the support of Demcon Multiphysics, we perform Monte Carlo simulations using FLUKA, calculating key radiological quantities such as material activation, volumetric heat loads, fluences, and radiation-induced damage (dpa). These results guide the concept design of the target, surrounding equipment, shielding, and building infrastructure.

By combining FLUKA simulations with finite-element analyses, we ensure that all components meet strict requirements for thermo-mechanical robustness, minimal material degradation, and low radiation exposure outside the shield—supported by our in-house expertise in radiation transport, shielding architecture, thermal-flow design, mechanical engineering, and radiation-resistant materials.

curious how we can solve your technical challenge in the nuclear medicine field?

Contact me to discuss!