fume hoods.

Our multidisciplinary team combines expertise in biochemistry, system integration, and regulatory compliance with IVDR and FDA regulations to deliver certified products across microbiology, immunochemistry, and molecular diagnostics. We guide clients through the entire product development process employing a structured yet flexible development process that adheres to ISO 13485 standards and emphasizes high-quality design, reducing development risks and therefor minimizing time-to-market while predicting and managing associated development costs.

We leverage our extensive experience with various samples and detection techniques, utilizing advanced fluidic control and optical systems to enhance assay performance. Our support includes concept generation, early proof of concept setups, and developing tools for assay development. Additionally, we provide visualization through 3D animations for marketing and training purposes and develop demonstrators that illustrate the functionality of your IVD products.

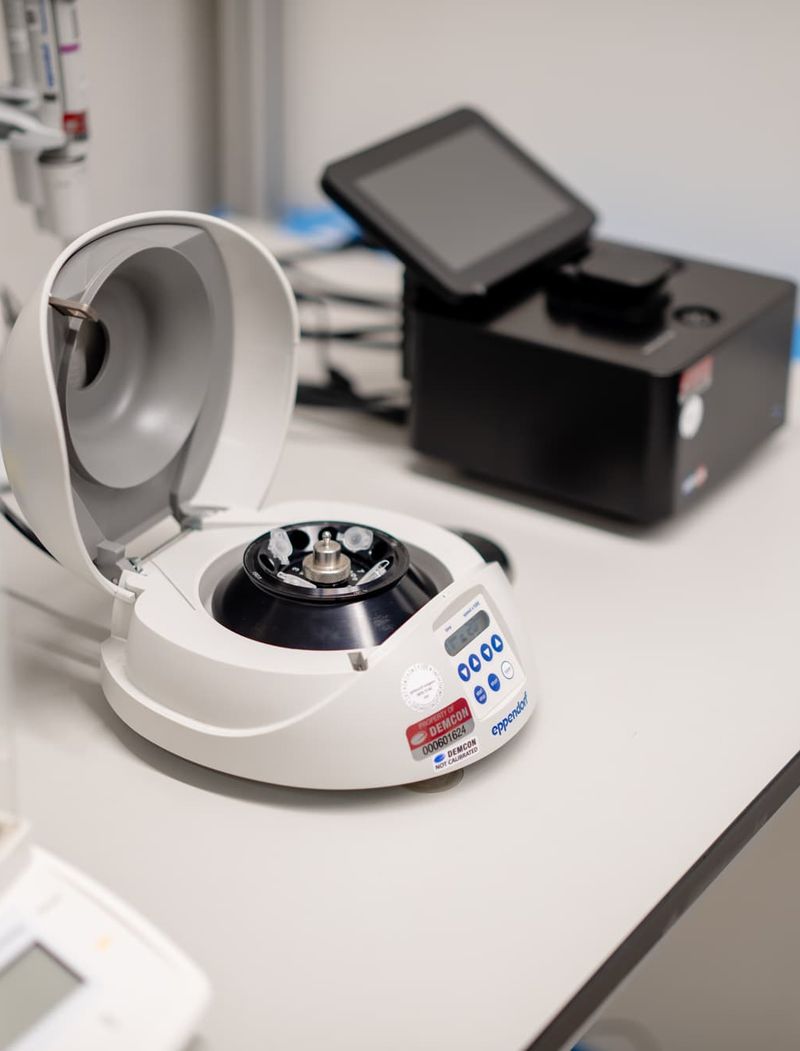

We have our own in-house wet-lab, where we conduct advanced testing and verification for In-Vitro Diagnostic (IVD) products. This dedicated facility enables us to rapidly develop and test prototypes during development while ensuring compliance with strict quality standards and regulations. With this capability, we can accelerate the development of reliable and optimized IVD systems for the life-sciences and healthcare sector.

Within the Demcon group, we benefit from seamless cooperation across various entities, tapping into specialized expertise in industrial systems, production, thermal, optical, data, AI, and FEM simulations. Our commitment to complex systems includes early design input from in-house production engineers to optimize manufacturability. For new product introduction (NPI), we establish efficient supply chains, conduct supplier evaluations, and develop production tooling and processes.

Fill in our contact form if you want more information and discuss how we can support your device development.

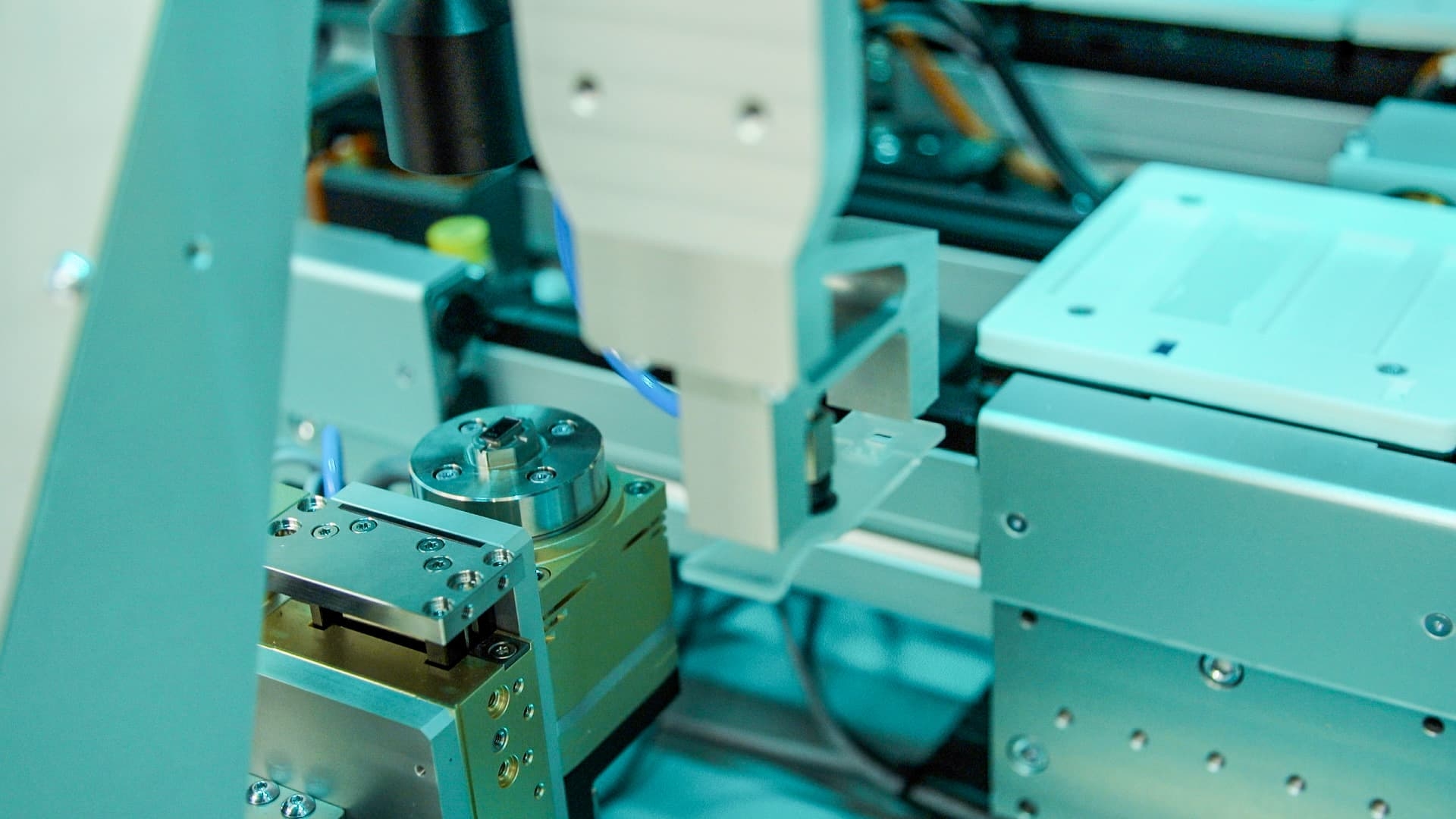

Accelerate spatial genomics with Demcon’s automated analyzer—high-throughput, precise imaging for advanced mRNA research.

Read more

Explore how biotech innovations like single-use tech, advanced sensors, and automation drive efficient cell culture manufacturing for therapies and biopharma.

Read more