highlights

- Novel radionuclides boost diagnostics and therapy.

- Production demands call for new methods.

- Accelerator facilities face complex challenges.

- Efficient harvesting ensures purity and safety.

- Multi-disciplinary design speeds up solutions.

challenges in every step of the supply chain.

Designing systems and processes that allow radionuclides to reach patients poses challenges in every step of the supply chain: production, followed by distribution and harvesting, and end-delivery to the patient. Meeting requirements for radiation protection, component radiation resistance, and compliance to good manufacturing practice (GMP) are essential at each step.

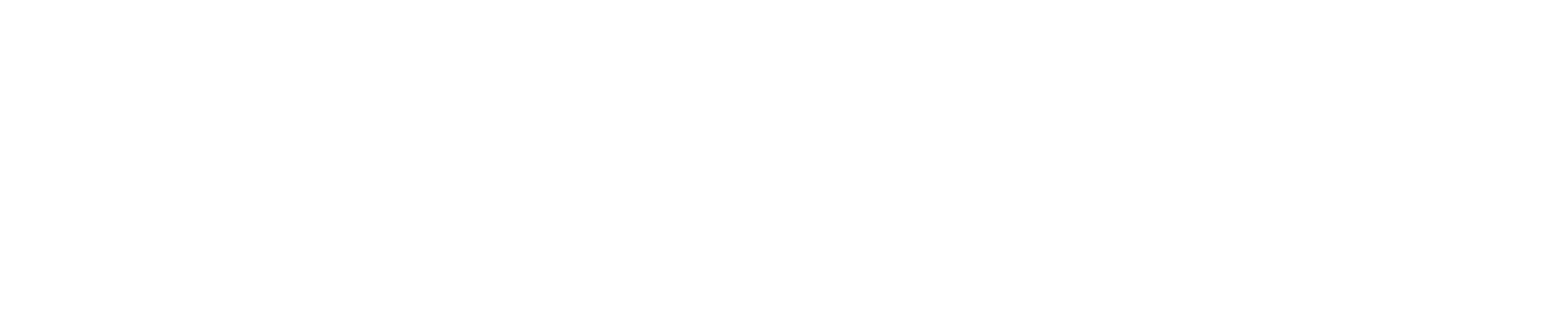

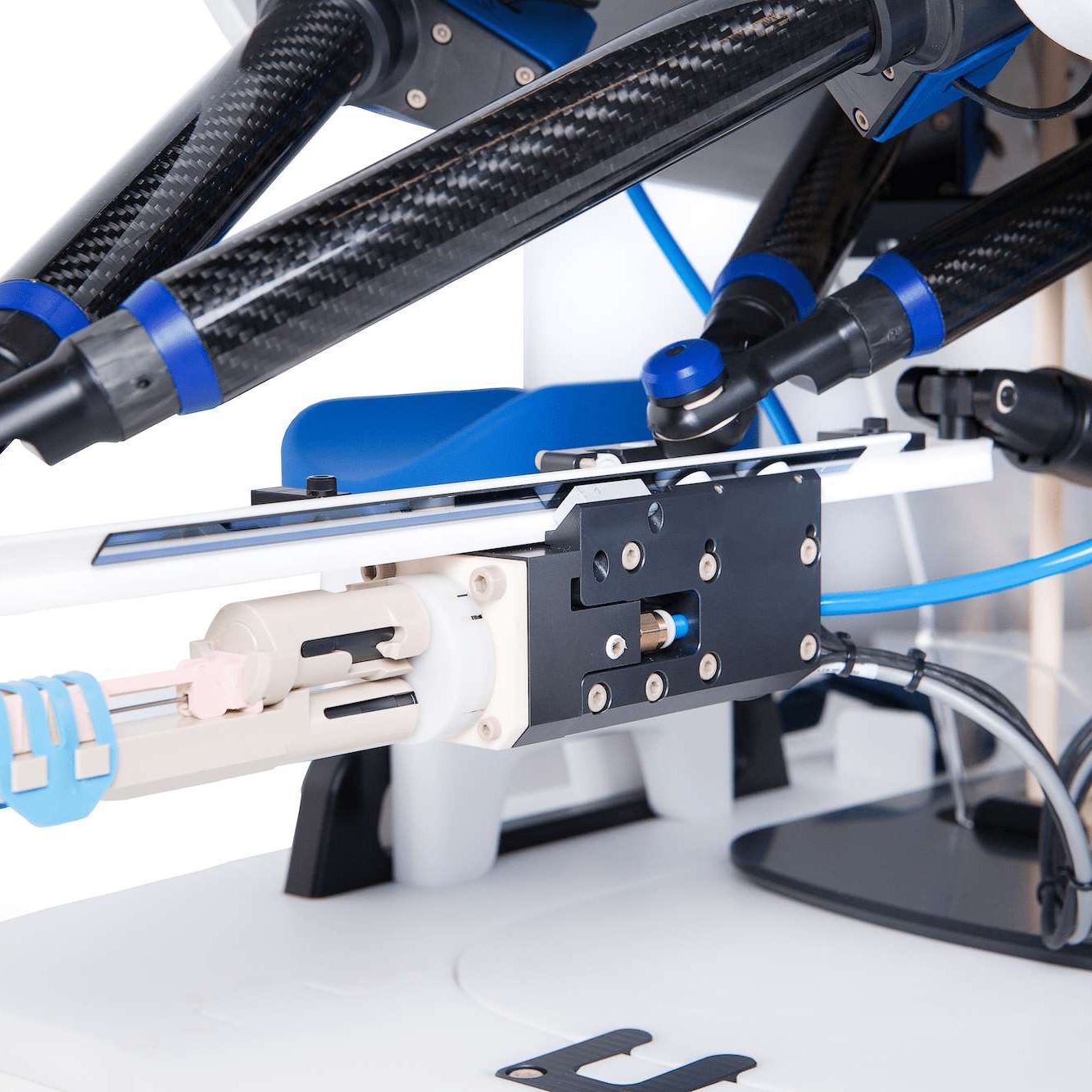

tailor made devices and tooling for production and delivery.

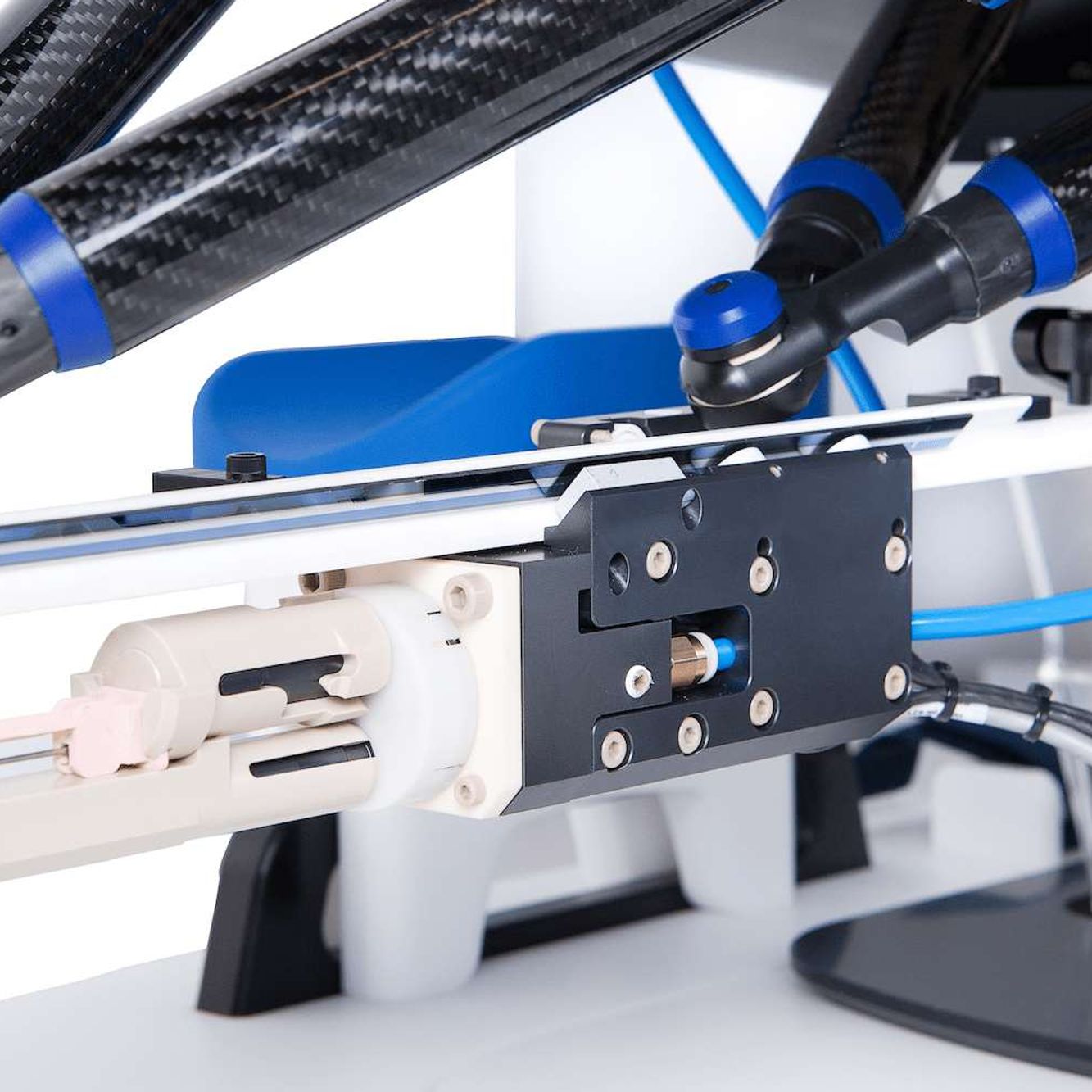

For production, the core requirement is to generate high specific activity. For new accelerator facilities, the engineering challenges magnify enormously in scale and time, due to the high intensity of irradiation. Some of the drivers for complexity are beam induced heating, radiation damage, and radioactive waste production and decommissioning. For new harvesting technologies, the core requirement is to efficiently separate pure daughter isotopes, that can be timely labeled and transported to the end users. Unique isotope decay modes call for tailor-made systems that are compliant with radiation exposure limits.

the results.

The above design approach is used to develop various radionuclide production systems. For example in the SMART project, where the above discussed challenges pushed the limits of technological feasibility. This multi-engineering design approach led to important choices for the cooling concept, modularity and shielding design. These choices were verified in successful feasibility tests.

"what about a multi-engineering approach?"

New routes of radionuclide production are challenging, but a multi-engineering approach can help achieve comprehensive solutions for all steps in the supply chain, thus bringing the novel radionuclides successfully to the patient.